pashi

helps

you

pashi

helps

you

reduce production line shutdowns

Cumulative revenue loss

$0

07:00AM

Cumulative revenue loss

$0

Line A is down due to a critical overheating warning in the tube forming machine. Ava, the lead production engineer, has been called in to solve this problem ASAP.

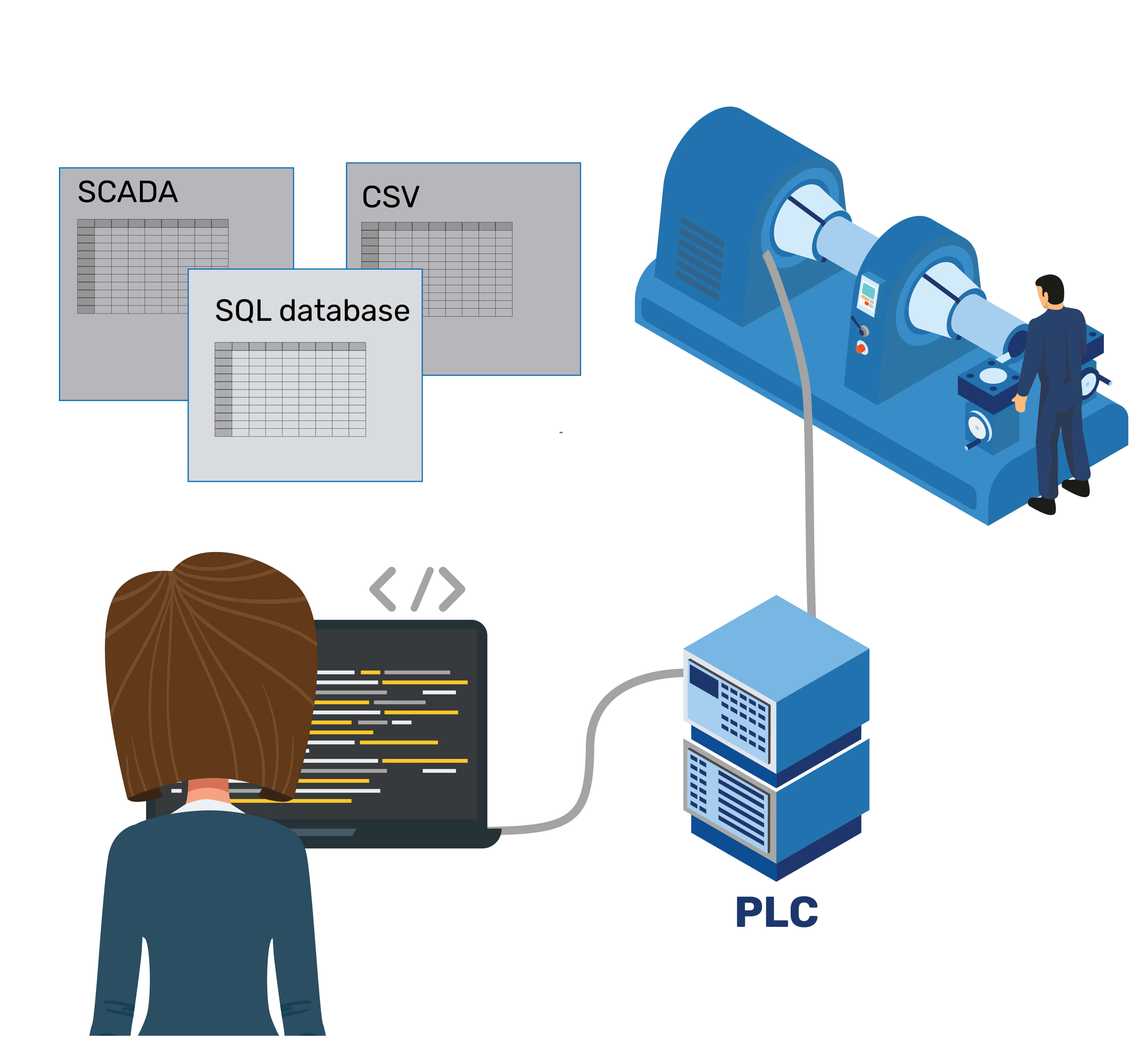

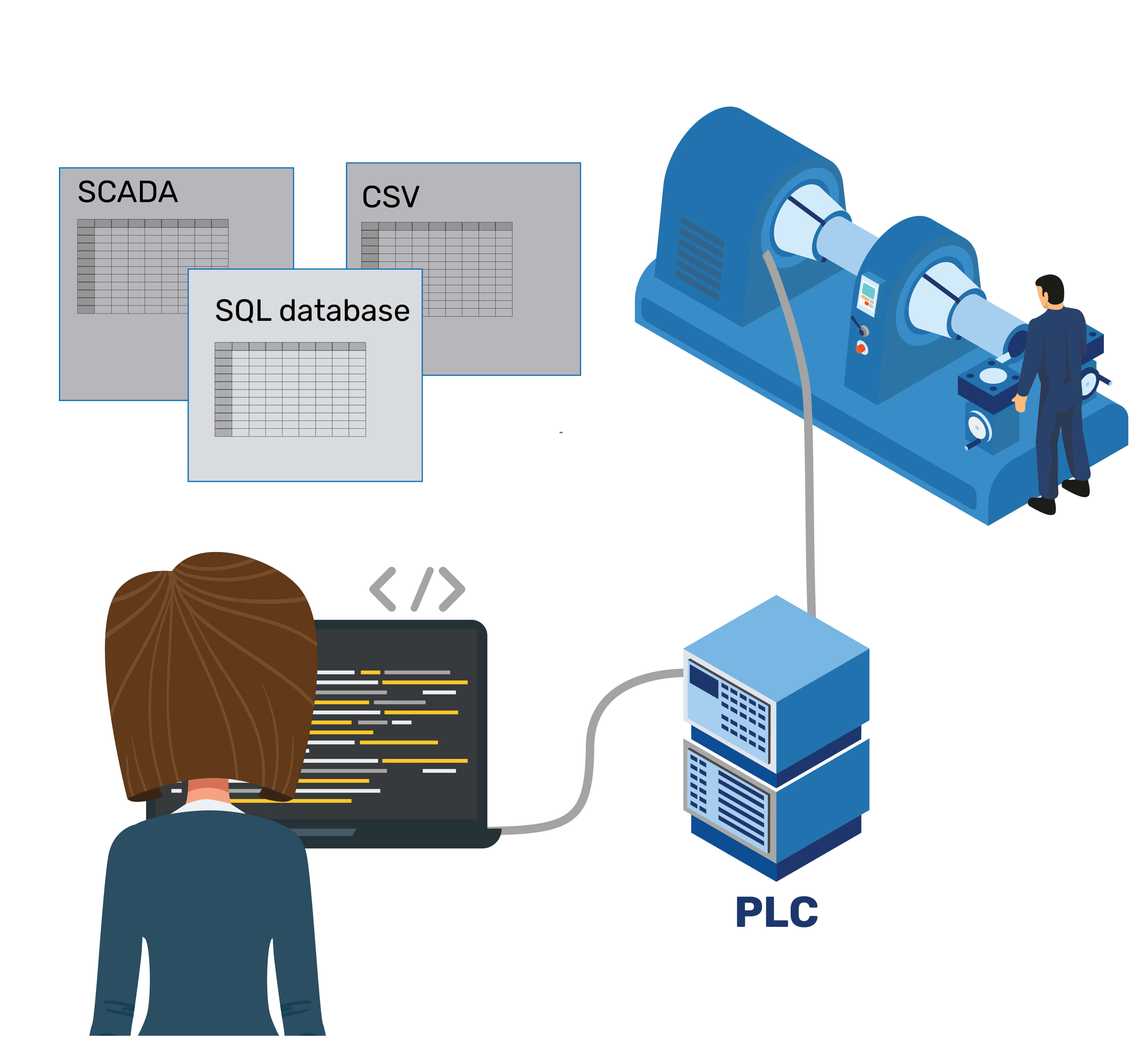

Ava immediately downloads the temperature sensor data files from the SCADA system to have a look at all the sensor data. The data shows the temperature has been spiking for a little while. She assumes that the heating coil is malfunctioning and calls a maintenance technician.

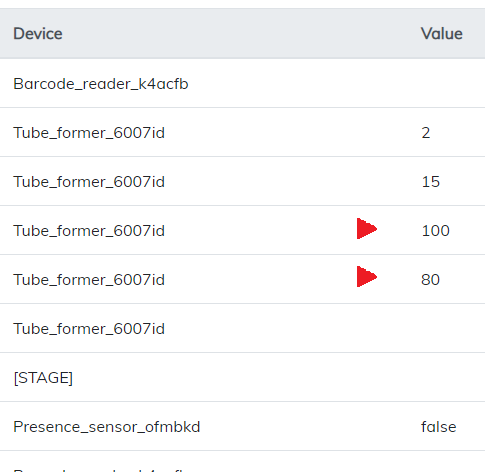

Ground-truth Device data

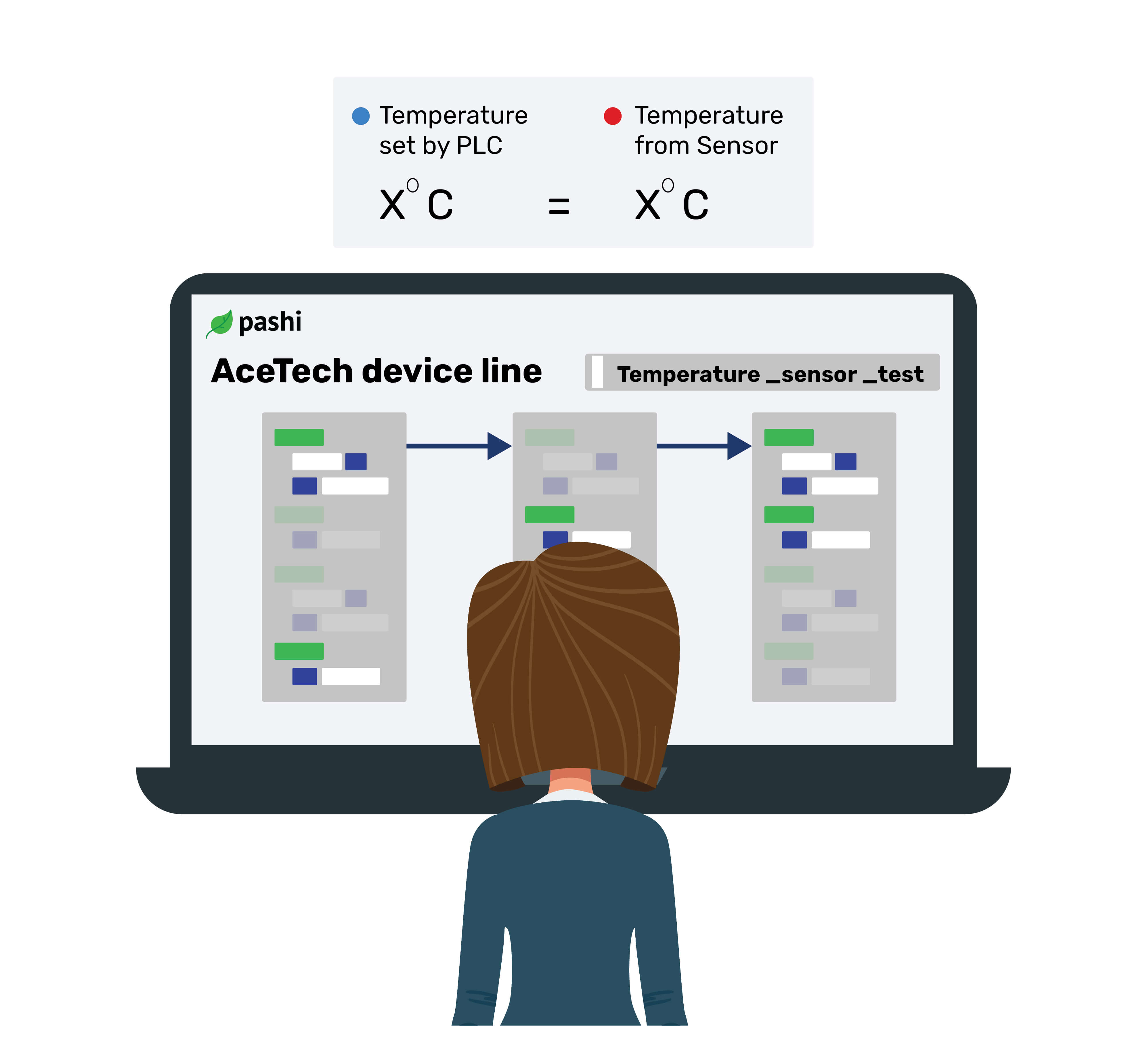

Pashi's Analytics view lets you inspect data from your machines in an easy, accessible way at a single location.

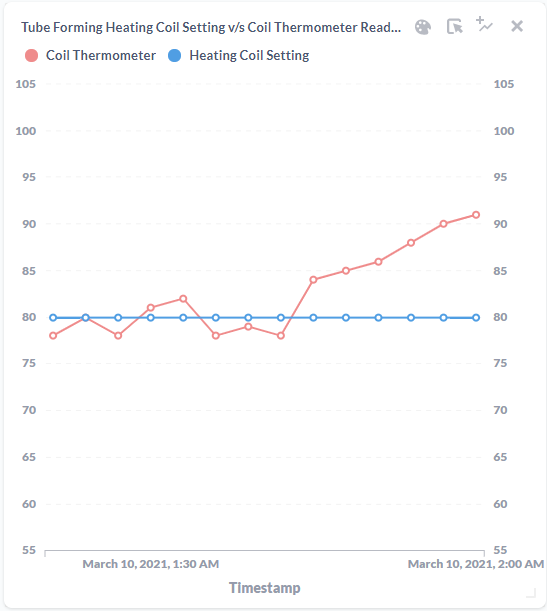

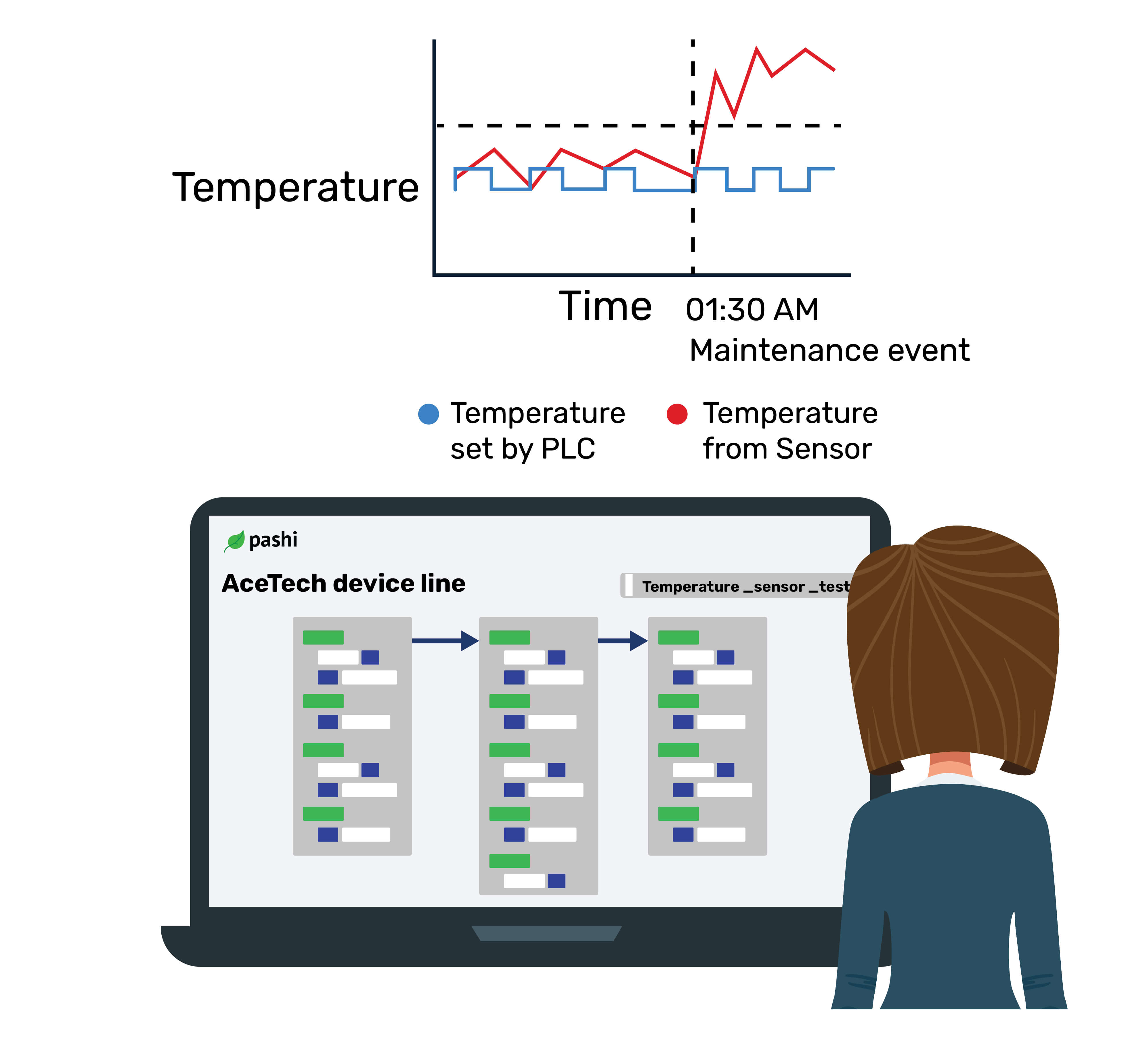

Ava immediately opens Pashi’s analytics tab and graphs the temperature that the PLC was attempting to drive the coil to and the temperature values recorded by the sensor installed in the machine on the same axes. She finds a divergence between these two values starting from 0145 hours the previous night, and notes that the mix of materials and SKUs did not change based on the labelling of the individual product data points on the graph. She immediately calls on a maintenance technician to check on the coil.

The day-shift maintenance technician arrives, runs some tests on the coil and pronounces that it is working correctly. Confused, Ava wonders if there is a mistake in the logic in the PLC that was driving the coil to incorrect temperatures, but this data is stored separately. She spends some time finding the right interface program to extract the data in CSV format from the PLC’s attached Historian module.

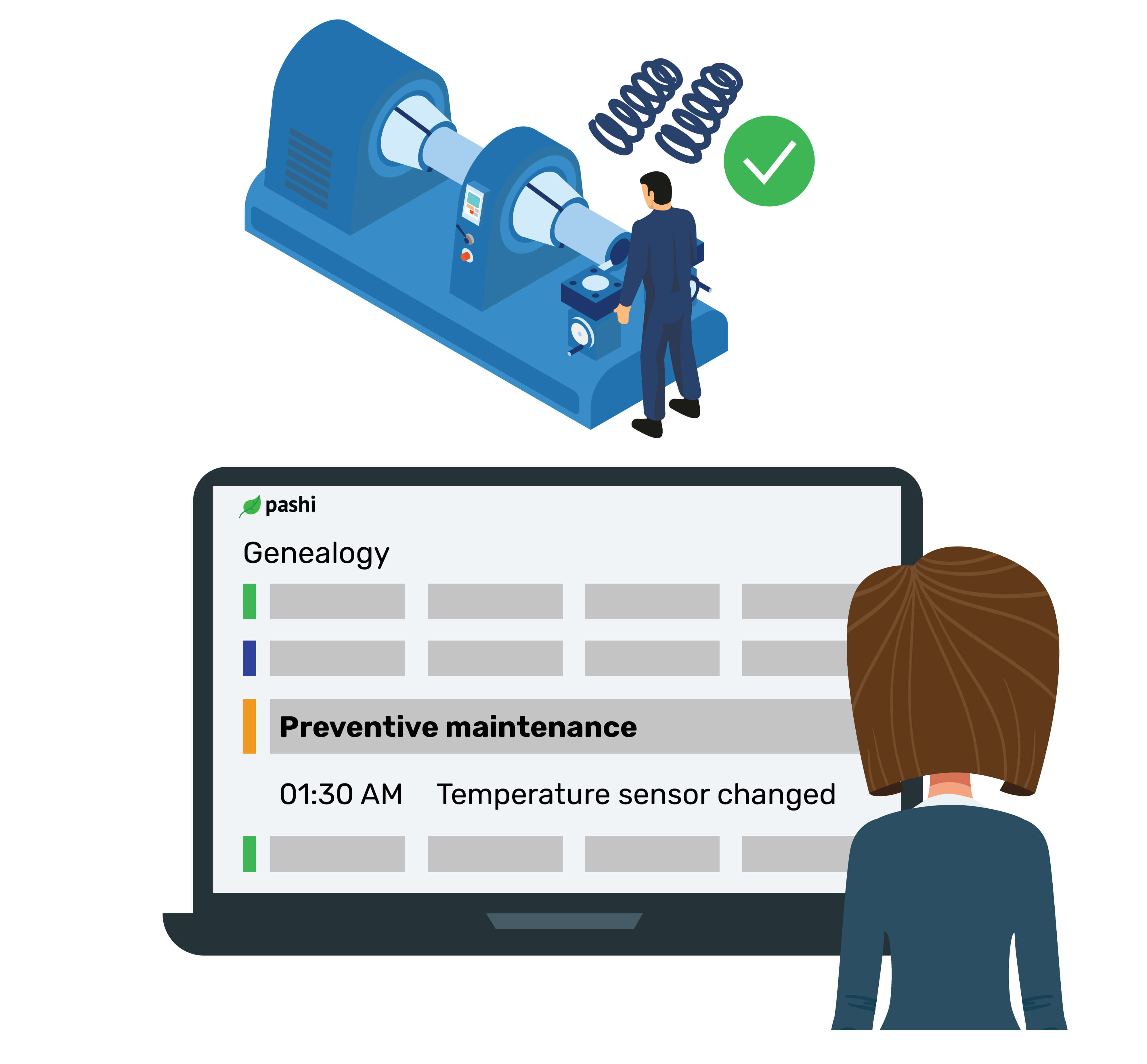

Device Status History.

The Genealogy offers a timestamped historical record of the statuses of all devices on the production line.

While the day-shift maintenance technician checks the coil, Ava checks all events that Pashi has recorded about this machine and related devices around the time of divergence. She notices a total preventive maintenance ticket on the sensor at 0130 hours. At the same time, the day-shift maintenance technician declares that the coil is working fine, leading Ava to suspect that the temperature sensor is at fault. She calls the night-shift maintenance technician who handled the ticket into the factory.

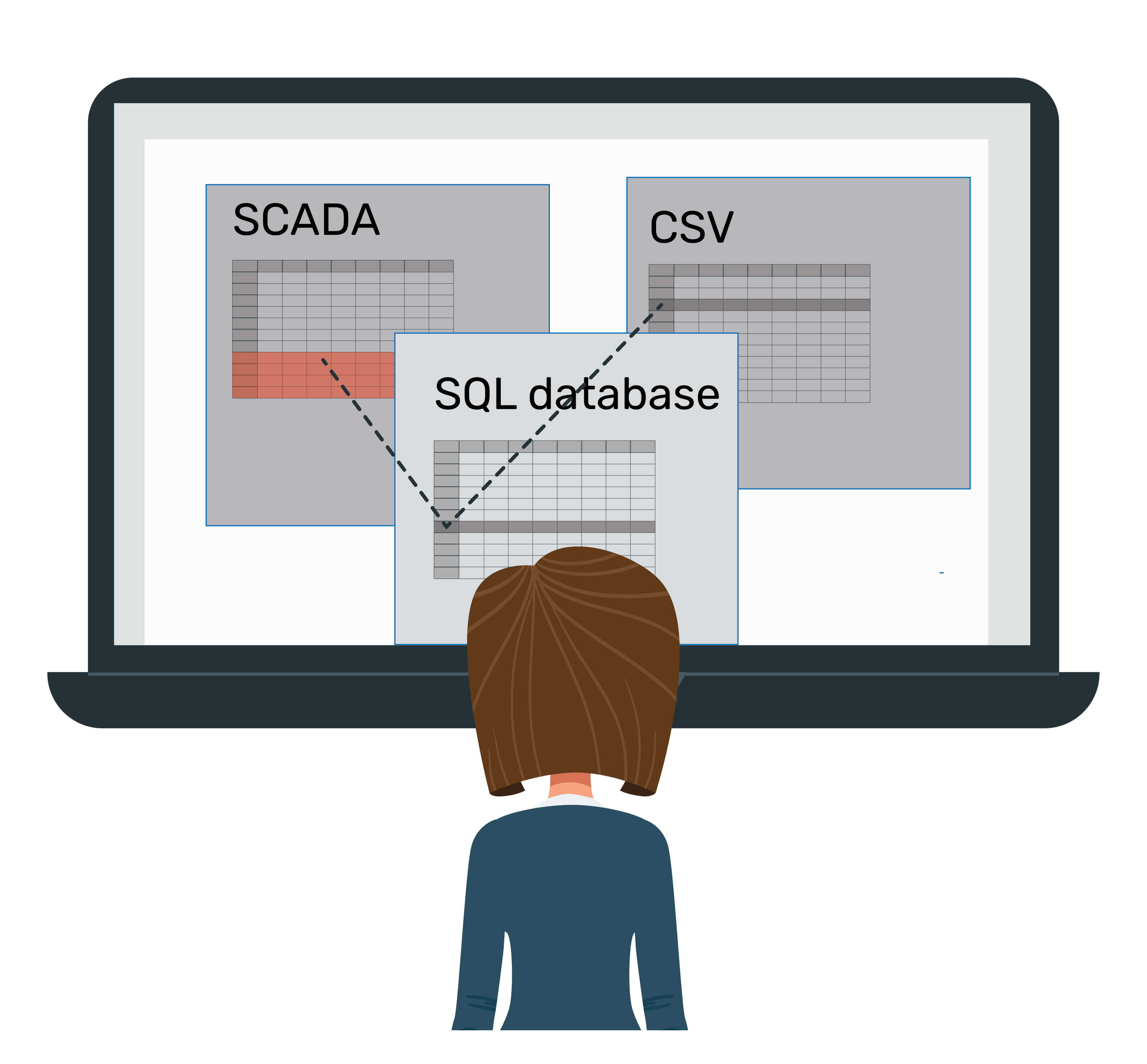

After extracting the data, Ava finds that the timestamp format on this CSV does not match that of the SCADA system. She begins manipulating the data in Excel to align both the dataset formats.

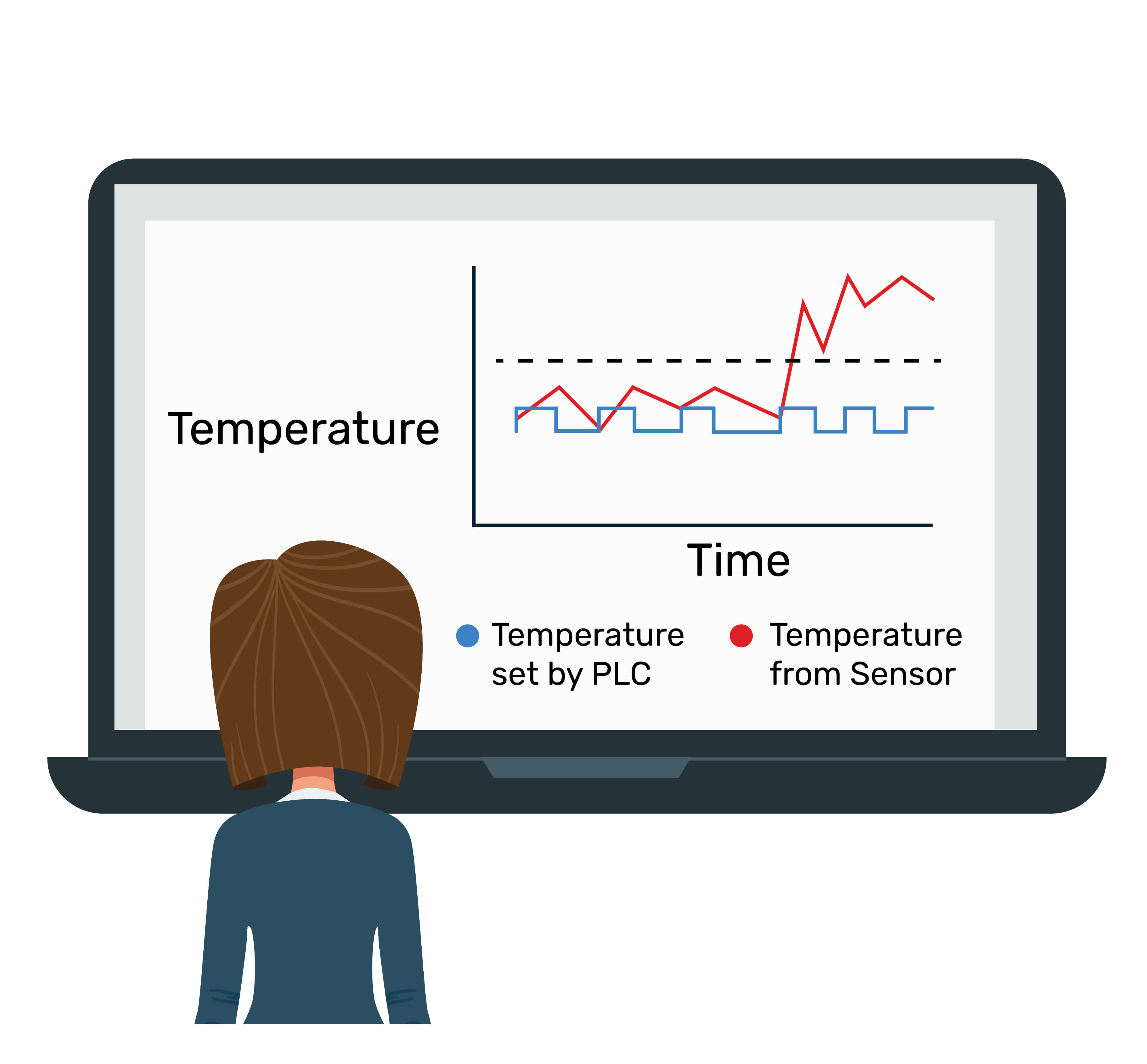

Live Monitoring & Debugging.

Pashi's Live view lets you compare process variables in real-time.

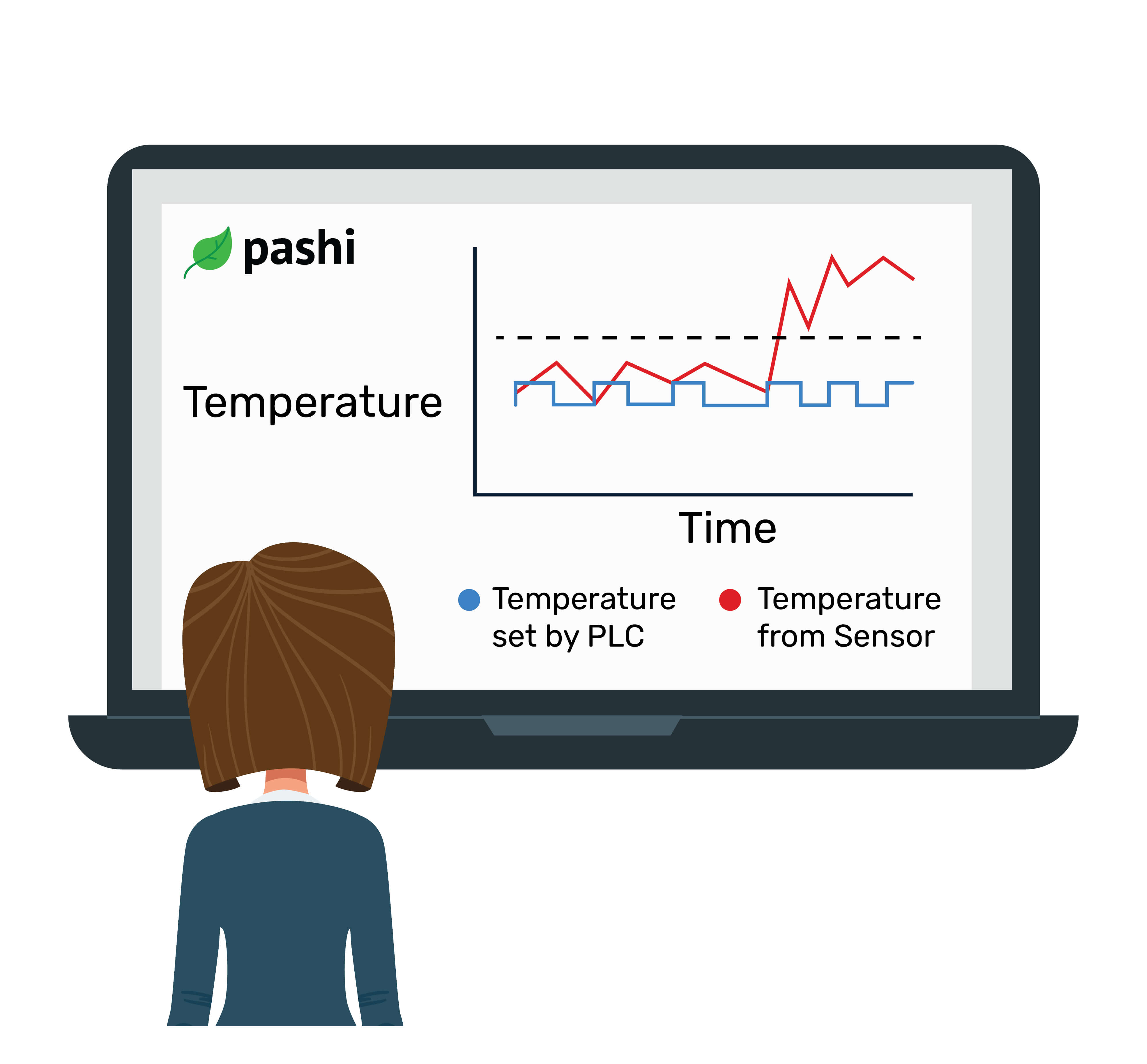

While the night-shift maintenance arrives, Ava sets up a test Pashi Program to confirm that the temperature sensor is recording different values than the PLC controlling the machine is setting the coil to, by using an external temperature sensor that she is able to temporarily connect to Pashi.

Ava and her team are still working with data manipulation software and Excel sheets to make sure the two datasets align without errors.

Finally, the maintenance technician arrives and works together with Ava to establish that the temperature sensor was miscalibrated the previous night. Ava requests the night shift maintenance technician to recalibrate the sensor.

Finally the team manages to merge the files and notices that the temperature readings from the sensor and the temperature that the PLC was driving the coil to diverged at 0145 hours the previous night. Ava is at a loss as to why this has happened and decides to begin with the logs.

Switch between Test and Stable Versions

View all earlier versions of line logic in the Current Version panel and revert to the version you need.

After recalibration, Ava uses the test program to verify that the temperature sensor is now calibrated correctly and is reading values which match those set by the PLC. Ava then restores the Pashi Program to its original version and restarts production without incident.

After painstakingly digging into various other logs to eliminate factors like power surges and raw material quality issue, Ava finally finds the root cause: a routine total preventive maintenance ticket in the maintenance log to replace the heat sensor, completed at 0130 hours last night. She asks for the night-shift maintenance technician who handled the ticket to come to the factory.

The night-shift maintenance technician arrives and after reviewing the machine informs Ava that the sensor was miscalibrated. He then spends some time recalibrating the sensor and bringning the maching back online. Ava gets her PLC programmer to write a dummy program for the PLC to test if the sensor is reading the right values based on the impulse to the coil. Once they verify that this works, they reload the original program onto the PLC and restart the line.